PFI delivers custom made foam packaging designed to cushion, protect, and streamline your supply chain. From die-cut inserts to high-performance ESD and XLPE foams, we help manufacturers reduce damage, cut costs, and safeguard products in transit.

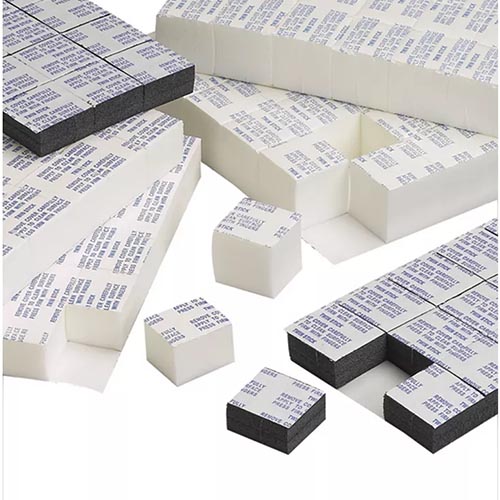

Custom die-cut foam inserts are precision-engineered to fit your products perfectly, preventing shifting and absorbing impact. Ideal for electronics, instruments, and fragile industrial parts.

Foam end caps cushion products on all sides, keeping them secure during transit and storage. Designed to absorb shock and resist vibration, they’re perfect for appliances, electronics, and delicate components.

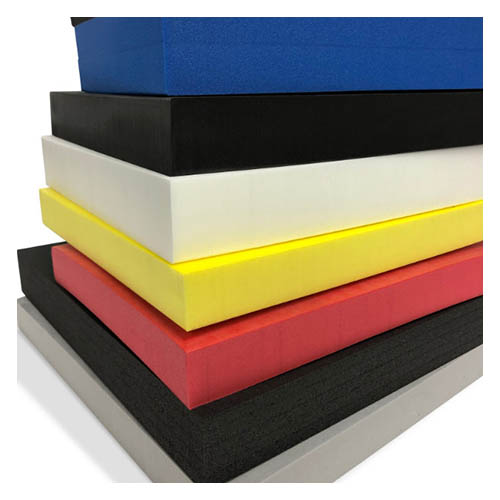

Foam sheets and planks are cut-to-size solutions perfect for layering, blocking, or custom fabrication. They deliver consistent protection across a wide range of applications.

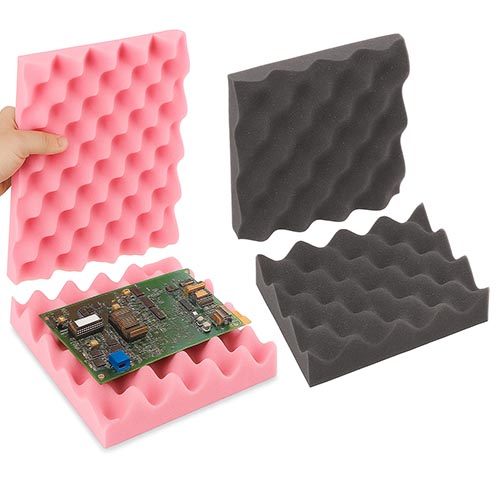

Also called “egg crate foam,” convoluted sets offer lightweight, cost-effective cushioning. Excellent for delicate instruments, electronics, and reusable cases.

Lightweight yet strong, molded EPE/EPP foams are impact-resistant and moisture-resistant. Perfect for automotive, electronics, and industrial packaging.

EPS foam delivers rigid, lightweight protection. Commonly used for molded blocks, corner guards, and trays—ideal for shipping fragile or bulky items.

A premium foam with a smooth finish, XLPE combines durability and aesthetics. Excellent for medical devices, aerospace components, and high-end products.

Soft, cushioning foam that conforms to product shapes. Perfect for fragile items like glassware, instruments, and electronics.

Closed-cell PE foam provides durable protection with moisture and chemical resistance. Great for blocking, bracing, and industrial packaging.

Engineered for electronics, ESD foam prevents static buildup while providing cushioning. Available in conductive and antistatic formulations.

Foam cushions distribute weight evenly and absorb shock. Essential for protecting items from stacking and handling stress.

PFI’s custom foam solutions provide reliable cushioning for fragile, sensitive, and high-value products. We design foam packaging that absorbs shock, prevents vibration, and keeps items secure during shipping and storage. With CAD-engineered designs, free prototypes, and a wide variety of foam materials, our packaging is tailored to meet your exact requirements. Whether you need lightweight foam sheets or specialized ESD-safe inserts, PFI has you covered.

Foam inserts protect bottles, cans, and perishables, preventing damage and keeping products fresh in transit.

Custom foam cushions fragile glass, tiles, and stone, absorbing impact and ensuring safe delivery to job sites.

Foam inserts secure décor, appliances, and electronics, reducing returns and enhancing retail presentation.

Engineered foam protects sensitive parts and tools, absorbing shock and meeting strict performance standards.

Dense foam stabilizes heavy drums and equipment, minimizing movement and preventing impact damage in transit.

Anti-static foam protects circuit boards and devices from vibration, shock, and static discharge during shipping.

Clean, non-abrasive foam safeguards medical devices and pharmaceuticals while maintaining sterility and safety.

Durable foam inserts protect parts and assemblies, improving packaging efficiency and reducing material waste.

Custom foam packaging protects products in transit while elevating unboxing presentation for retail shipments.

Lightweight foam enhances load stability, cutting freight costs and preventing product damage in long hauls.

Foam blocks and inserts protect furniture, mirrors, and décor from scratches, dents, and shipping damage.

Moisture-resistant foam trays cushion fruits, plants, and produce, maintaining freshness during transport.

PFI goes beyond being a foam supplier, we engineer complete packaging solutions that save money and reduce downtime. Our foam packaging services include:

Test packaging before you begin full production.

From polyurethane to ESD foam, we provide solutions for every industry.

Pricing that beats national competitors, typically by 15%-40%.

Next day service in Southern California and free nationwide shipping.

We provide local next-day foam packaging delivery across:

Multi-location businesses benefit from our nationwide distribution centers, ensuring consistent packaging supply wherever you operate.

From fragile electronics to industrial machinery, PFI delivers foam packaging that saves costs and reduces damage. Let us design a solution that works for you.

PFI supplies a full range of foam packaging solutions, including die-cut inserts, foam planks, convoluted foam, EPE/EPP, EPS, XLPE, polyurethane, polyethylene, and ESD foams. We also provide top and bottom cushioning, as well as foam bracing. Each option is engineered for specific applications, ensuring your products receive the protection, stability, and durability they need in transit.

Yes. PFI specializes in custom foam packaging tailored to your exact product dimensions and handling needs. Using CAD design and free prototypes, we create inserts, blocks, and cushions that secure fragile or high-value items. From small electronics to heavy industrial components, our foam is engineered for a precise fit that reduces damage and lowers shipping costs.

Foam packaging is widely used across electronics, aerospace, automotive, medical devices, consumer goods, and industrial manufacturing. Industries choose foam for its shock absorption, vibration resistance, and ability to safeguard sensitive equipment. PFI tailors foam solutions to meet strict standards, ensuring compliance and consistent performance no matter your sector.

EPE/EPP foam is lightweight yet impact-resistant, making it ideal for automotive, industrial, and electronics packaging where flexibility is important. EPS foam, on the other hand, is rigid and lightweight, commonly used for molded blocks, corner guards, and trays. Both foams are excellent for protection, but the choice depends on your product’s weight, fragility, and environment.

Yes. PFI supplies ESD foam that prevents static buildup while providing cushioning. Available in both antistatic and conductive formulations, this foam is essential for electronics, circuit boards, and sensitive components. By using ESD-safe foam, you reduce the risk of electrostatic discharge damage while ensuring safe, reliable product protection during storage and transit.

CAD design allows PFI to engineer foam inserts and packaging with precision. By creating a digital prototype of your product, we design custom cutouts and inserts that fit perfectly. This process reduces trial and error, speeds up production, and ensures the foam provides exact protection where it’s needed most. Free prototypes let you test designs before full runs.

Many foam options, such as polyethylene and EPE/EPP, are recyclable, and PFI works with clients to minimize waste by optimizing designs. Additionally, pre-stretched films and reusable foam solutions can lower material use. While not all foams are biodegradable, we help you select the most sustainable options without compromising protection or performance for your products.

PFI provides next-day delivery across Southern California, including Orange, Los Angeles, San Diego, Ventura, and Riverside counties. For businesses outside the region, we leverage nationwide distribution centers to ensure fast, reliable delivery. With Vendor-Managed Inventory (VMI) and Just-In-Time (JIT) programs, we make sure foam packaging arrives exactly when you need it.

Foam packaging offers superior shock absorption, vibration resistance, and cushioning compared to paper or cardboard fillers. It conforms to product shapes, providing tailored protection that reduces damage and returns. Specialized foams, such as ESD or XLPE, also offer added benefits, including static control, water resistance, and smooth finishes, making foam the ideal choice for high-value items.

Requesting a quote is simple. Just fill out the Request a Free Quote form on our website or call our team directly. Provide details such as product type, dimensions, volume, and any special requirements, including ESD protection or foam lining. Our engineers will design a tailored solution and send you a competitive quote, often within one business day.